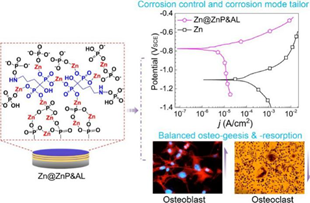

Bone fracture remains a major public health concern. Internal fixation devices are commonly used in clinical practice for the bone healing. Nowadays, permanent or non-degradable metals are utilized for the fabricating materials, which brings about inevitably side effects and requires usually a second surgery to remove the implants after the bone healing. The concept of biodegradable becomes a new paradigm for the next generation of bone fixation implants and Zn-based metals have been considered as the leading candidate materials. However, their uncertain degradation/corrosion behavior as well as insufficient bio-compatibility/-functionality hinders their clinical translation. Surface modification offers a great avenue to address this key issue, most of current research remains still far from satisfactory from the standpoint of clinical application. Recently, a novel alendronate embedded zinc phosphate hybrid coating was constructed on Zn by Prof. Guojiang Wan’s group, which has been published on the academic journal Corrosion Science. The hybrid coating combined the desirable corrosion protective property and potential bio-compatibility. Thanks to its high quality, the hybrid coating serves as a effective kinetic barrier to slow down the corrosion rate of Zn as well as reduce the Zn2+ release. Moreover, the coated Zn turned to a more uniform corrosion mode, free of severe localized corrosion, which is beneficial to maintain a structural and mechanical integrity of the implants during the degradation process. More importantly, the coating shows a great potential for bone repairing functionality with a good balance between the bone formation and resorption.

For more details, please refer to this article(Xiaoshan Mo et al, and Guojiang Wan*, Corrosion Science 184 (2021) 109398): https://doi.org/10.1016/j.corsci.2021.109398